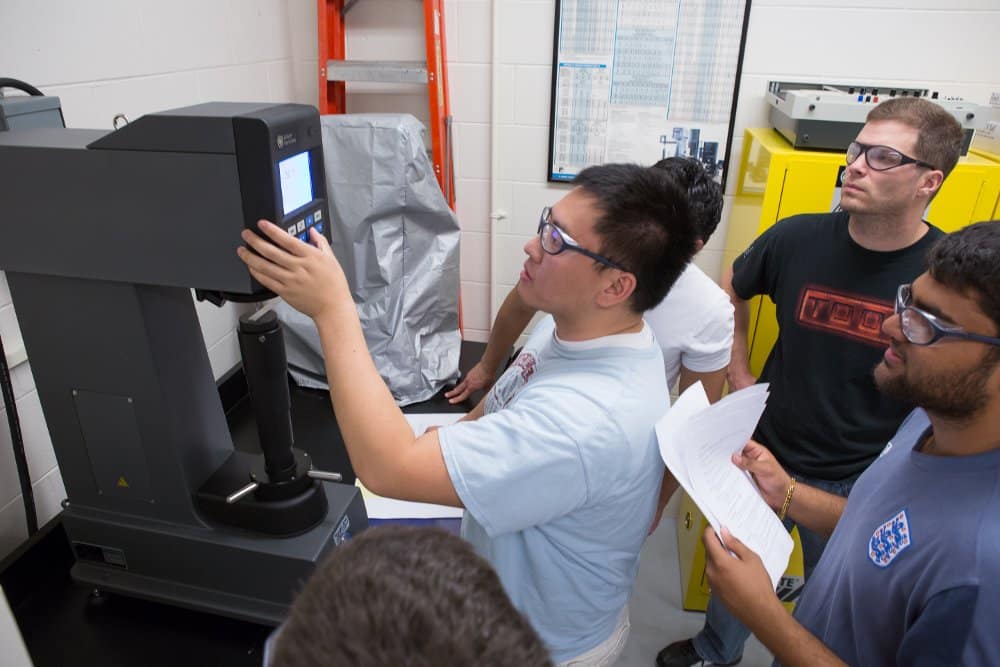

Observation and alteration of material performance, including the fabrication of novel materials and measurement of their properties, occurs in the Materials Testing Laboratory.

The concepts and theory given in engineering classes supporting undergraduate and graduate engineering programs are demonstrated and put into practice for reinforcement in this space, which is also the home of the laboratory class in aerospace structures and instrumentation. Some of the tests routinely performed in the lab include tensile, compression, hardness, heat treatment, microstructure evaluation, torsion, impact, strain, and NDE. Additionally, the space is used for fabricating and testing of cellular solids and composites by students, faculty, and partners.

The space is used for coursework in Aerospace Engineering, but also supports student projects and research associated with the Departments of Mechanical and Civil Engineering.

Equipment

- Screw-driven materials testing instrument

- Servo-hydraulic materials testing instrument

- Rockwell hardness testing machine

- Torsion testing machine

- Rotating beam fatigue testing machine

- Charpy impact testing machine

- Instrumented impact testing machine

- High-temperature box furnaces

- Metallurgical and stereo zoom microscopes with digital imaging

- NDE equipment

- Digital oscilloscope

- X-Y plotter

- Composite-cutting diamond band saw

- Composite-cutting diamond tile saw

- Water-lubricated cutting saw

- Sanding and polishing machines

- Ultrasonic cleaner

Lab Information

Location: LB 178

Lab Director: David Sypeck

Contact Us: To speak to someone about this lab or any of our facilities, call us at 386-226-6100 or 800-862-2416, or email DaytonaBeach@erau.edu.